Variable-Speed Drive Compressor and Adaptable Capacity Inverter

When it comes down to compressors, a variable speed drive (VSD) control is almost exactly the same as a variable frequency drive (VFD) in the way it controls an DC motor. However, compressors utilise a brush-less permanent magnet motor for improved efficiency and longevity.

The inverter (variable frequency drive) in these compressors generates three phases, with the frequency for each phase being fully adjustable below or above the average of 50/60 Hz normally used in the power grid. When the frequency is changed, the speed and, therefore, the rotations per minute, are also altered. For example, the electronic controller selects a speed between 1000 rpm and 4000 rpm but this will be different in every electro mechanical system. In addition, the speed that a compressor sets can also alter its cooling capacity.

As a general rule, compressor capacity will normally be in linear ratio to the speed. This means: when a 1:4 speed range has been set, the cooling capacity of the unit is likely to fall at around 1:3.7. Specific capacities are challenging to calculate, because each unit can differ depending on the parameters that have been set. With data sheets available to indicate the performance of variable speed drive compressors at different speeds, engineers can find the perfect speed and related capacity for their application requirements.

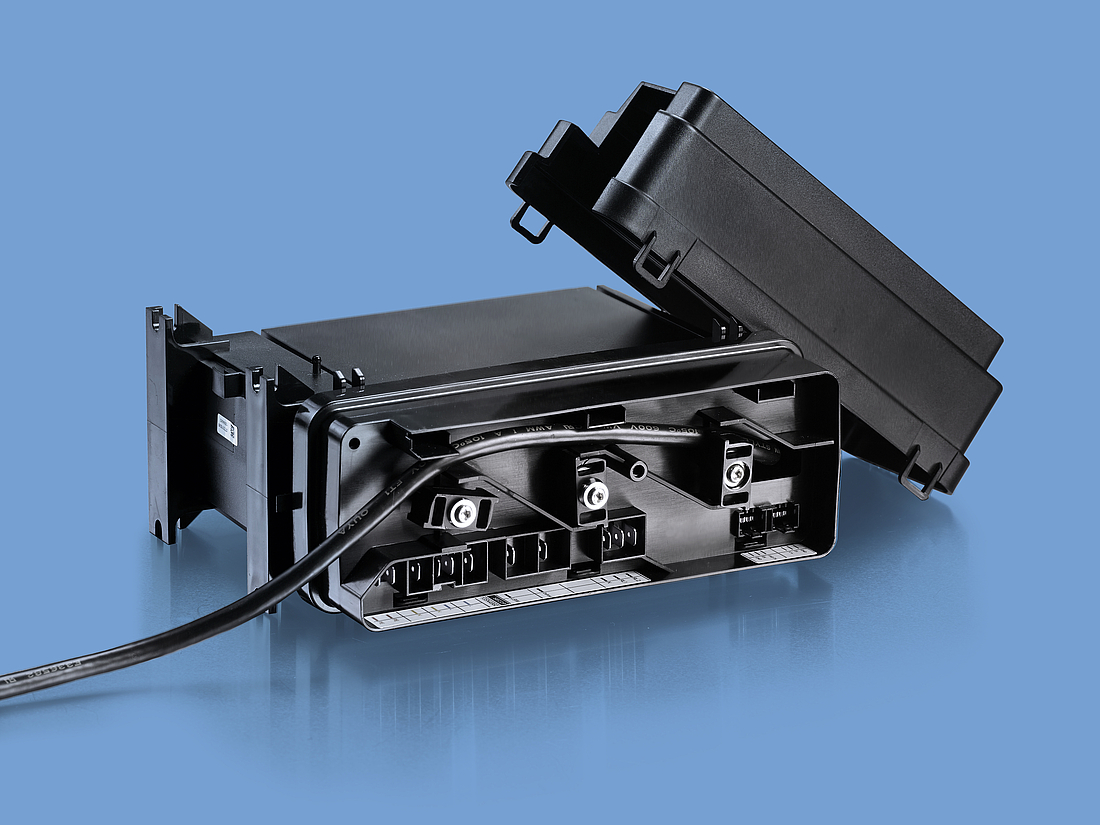

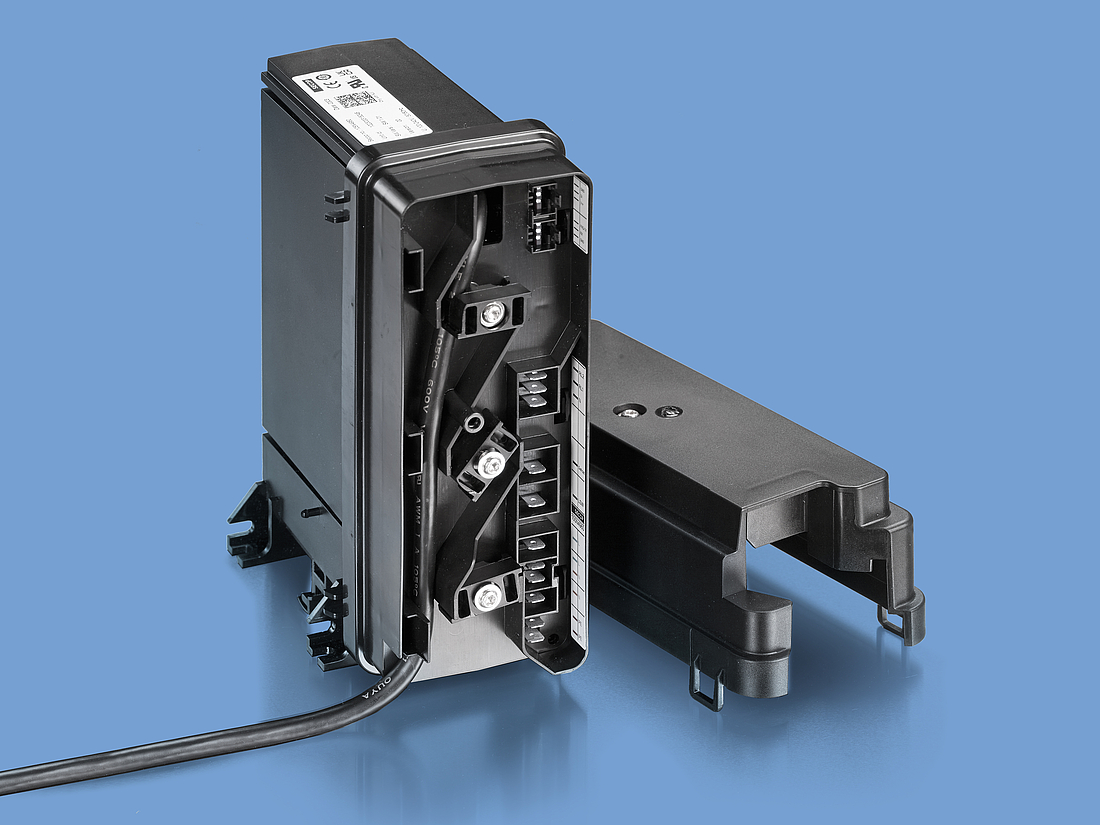

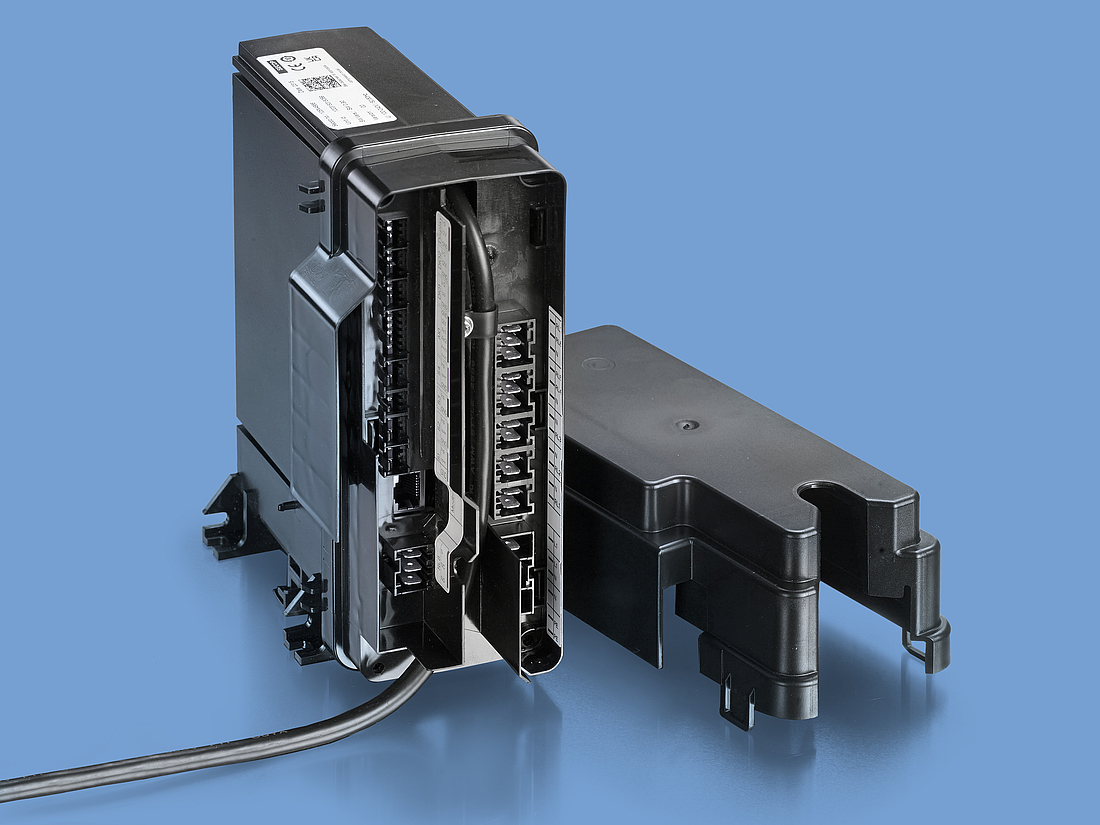

Aside from a compressor’s speed and capacity settings, it is also important to know about the relevant variable frequency drive (inverter) components. In the case of a variable speed compressor, the inverter is a small electronic unit with an input of 115/230 Vac (Voltage AC). The input is converted into three phases with efficiency levels being measured as high as 98 percent.

With components having such a high efficiency, it means that refrigerators developed using the variable speed compressors can benefit from reduced energy consumption.

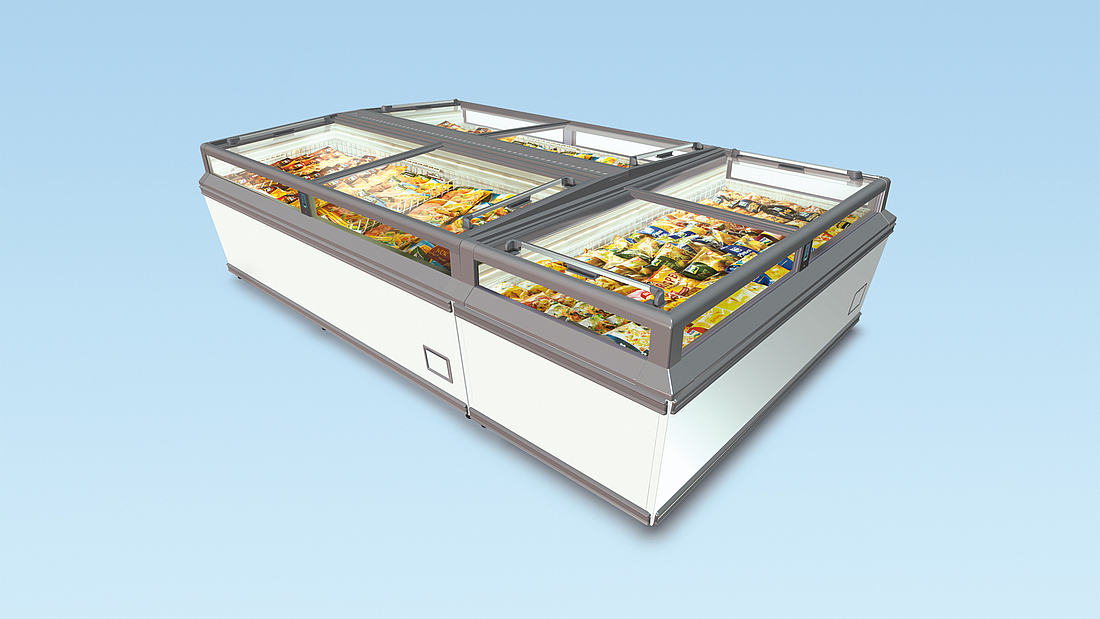

When using a variable speed compressor with an inverter (variable frequency drive) in a refrigerator, it is possible to lower the condensing temperature. In addition, a high evaporator temperature at low load rate can be applied. Meaning that when a refrigerator isn’t fully loaded, machines don’t have to work as hard to keep items cool. This can result in energy consumption savings of between 20 and 40 percent when compared against refrigerators that utilise a fixed speed compressor.

The most important advantage of variable frequency technology is adaptable capacity which leads to high efficiency.

Overall, a variable speed drive compressor offers engineers far more options when it comes to building electronic systems and products. By altering the settings for each individual device built, efficiency gains can be made that both benefit a business and the customer, i.e. the initial investment might be slightly higher applying a compressor with inverter but the operating costs and therefore the total cost of ownership will be significantly lower. Especially in high priced energy markets the payback time is extremely short.