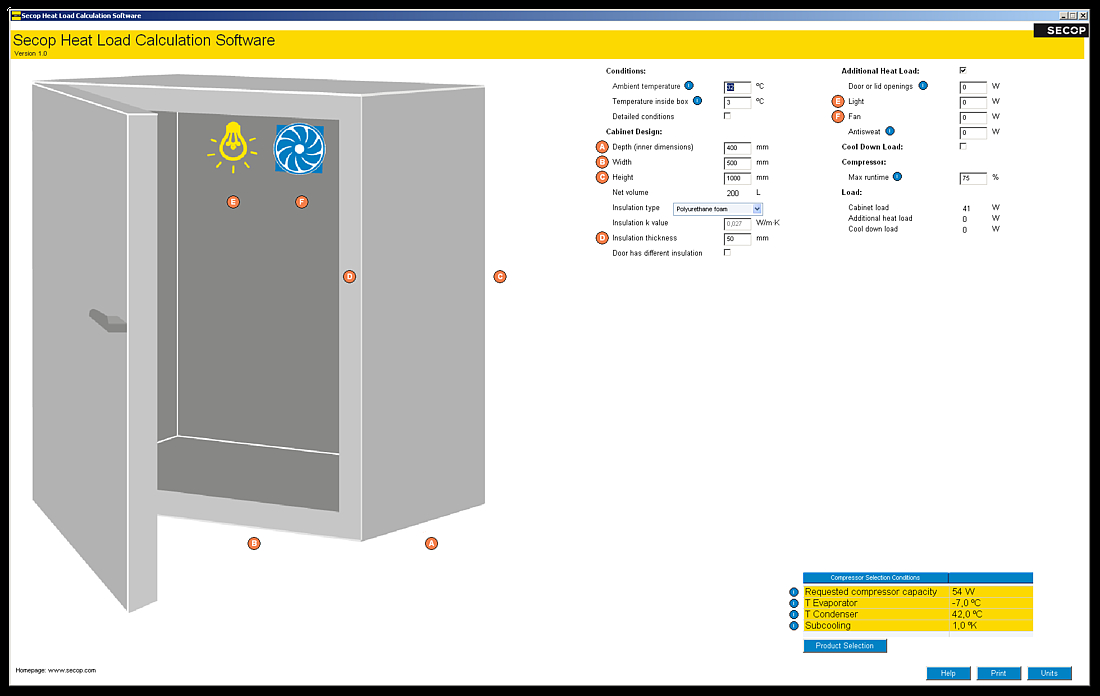

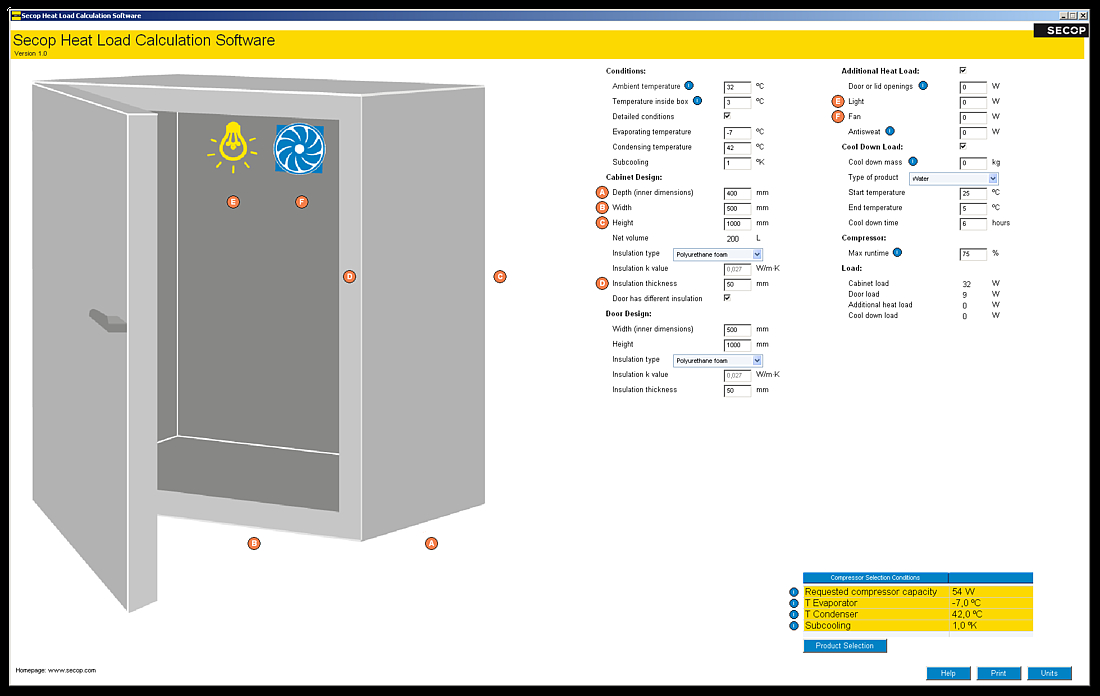

Heat Load Calculation Software

This software allows the user to calculate the heat load of a given application. Heat load is the amount of heat that must be removed from the cabinet (box) in order to maintain the target temperature.

It does not take into account if the load is different in a pulldown situation, e.g. during initial start or pulldown after defrost. The heat load will vary with changes in ambient temperature.

The philosophy behind the program is that basic input parameters are known to everyone, and no deeper knowledge of refrigeration is required.

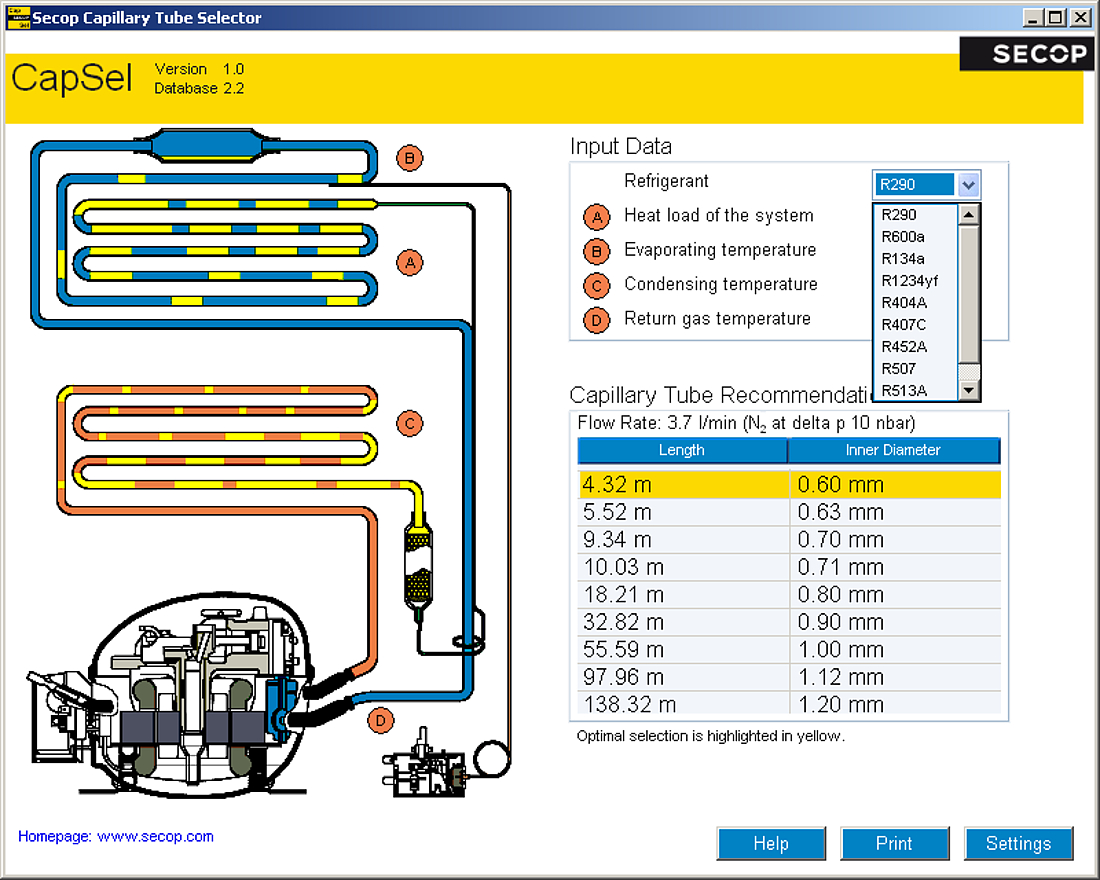

Input

The input values below are the minimum required to calculate the heat load

- Ambient temperature

- Temperature inside box

- Inner dimensions of the box

- Insulation type and thickness

In addition, “check boxes” can be opened for entering additional inputs and loads. See picture of extended view.

Calculations

The heat load calculation is based on the formula:

Q = k × A × Δt (heat load = k-value × heat transfer area × delta t)

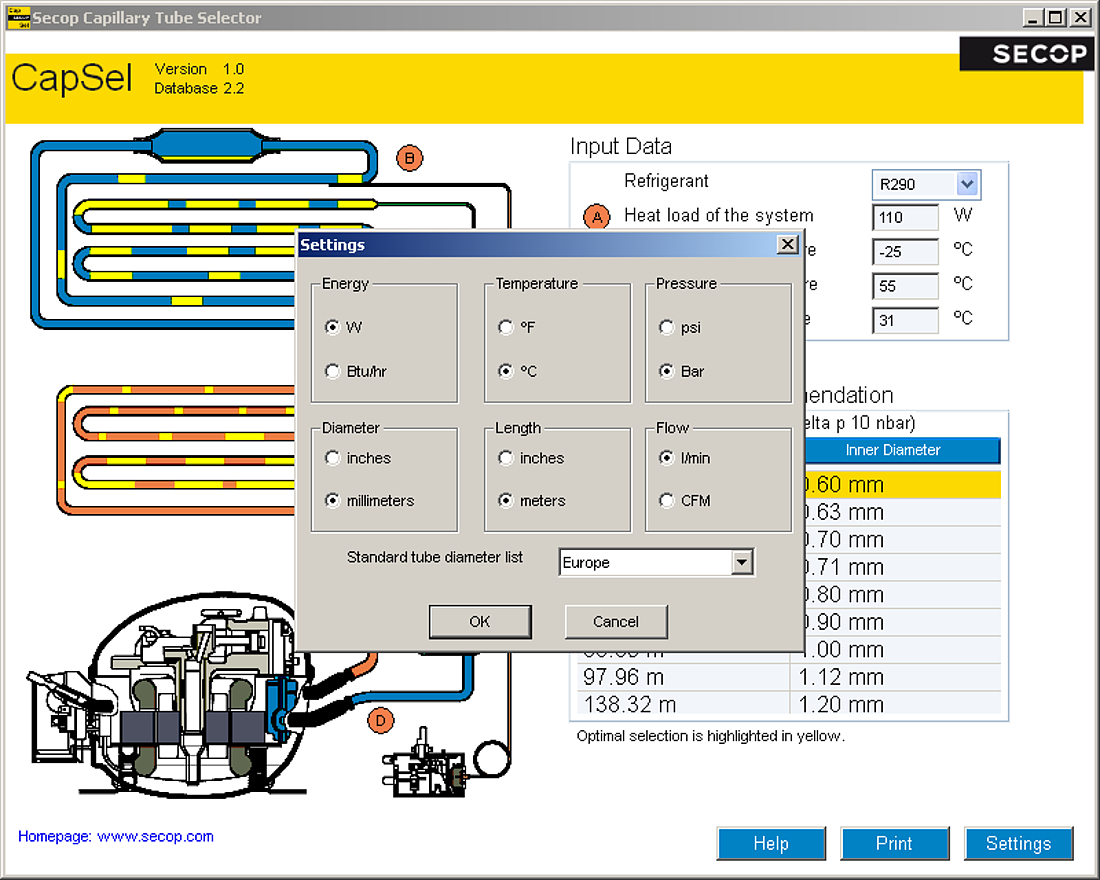

Units

It is possible to choose between different input units.

Context Help

For certain input values, an “I” in a blue circle indicates that holding the cursor over the “I” will display an additional explanation in a pop-up window.

Selecting the Compressor

After entering the input values, the compressor selection parameters will be calculated and shown.

By clicking “Product Selection”, you will be guided directly to the Product Selector where the proper compressor can be selected.

Download Secop Heat Load Calculation Software

Unzip and run "Setup.Exe".