Energy-Efficient Propane Plug-In Cabinets in Discount Retail Stores Driven by SLV Compressors

Energy costs are high in most European countries, especially in Germany, whereas sales margins in food retailing are low. To reduce the operating cost, AHT Cooling Systems (AHT) from Austria was approached by market-leading grocery chains to supply a self-contained display cabinet which has a much higher level of efficiency than the existing cabinets. According to studies, refrigeration in standard grocery stores contributes to 55% of the primary energy use.

AHT teamed up with Secop (Danfoss Compressors at that time) as one of their main compressor suppliers to work on a cabinet according to the specifications from the commercial end users.

About the System

Self-contained display cabinets are very common among food retail discounters in Europe as the small floor spaces do not favor large centralized installations. The single plug-in cabinets can be quickly rearranged if standing alone or installed in an island setup to be accessed by the customers from both sides. They usually contain frozen and low-temperature chilled food rather than dairy products.

The SLV-driven system has even more functionalities included for daily operation:

- HACCP control

- Alarm to signal failures which affect set temperatures

- Remote monitoring of temperatures and consumption

- Automatic defrost, ice accumulations on the inboard cabinet walls increase energy consumption due to insulation effects

- Control of illumination

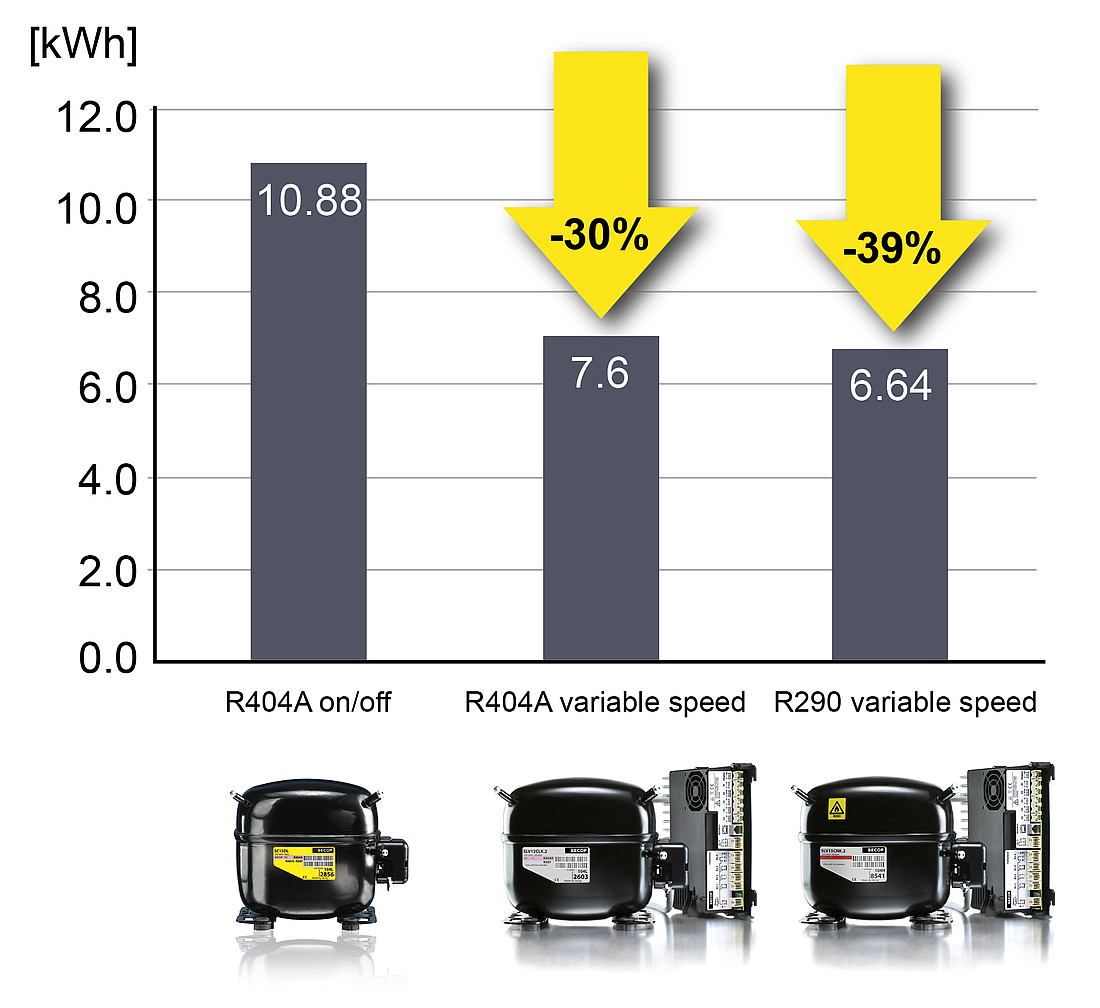

To reduce the refrigeration cycle's consumption of energy, Secop proposed to use an electronically controlled SLV compressor which is able to adjust its rotating speed and therefore the delivered cooling capacity. Secop’s experiences with variable-speed compressors have shown potentials to reduce energy consumption by up to 40% compared to a conventional compressor with a synchronous motor and fixed speed/cooling capacity running on/off.

Results

Intensive tests in labs and in the field have shown solid energy consumption savings. The graphic on the right shows the effect on cabinet efficiency using a variable-speed compressor but same refrigerant, which was observed to consume 30% less energy than compared to the identical system with a fixed-speed (on/off) compressor. The change towards R290 (propane) improved the efficiency by an additional 9%.

Additional savings are provided by secondary effects which include the scheduled (hot gas) defrosting of the cabinet and the full integration of application functions into one confroller, for example, fan and illumination control.

By integrating new compressor technologies into conventional applications and tailoring a solution for plug-in cabinets in discount retail stores, immense savings on total cost of ownership have been achieved. A major success for AHT which now has approximately 600,000 pcs on the market today.

Summary

Meanwhile, Secop has adapted the controls for SLV variable-speed compressors for the North American market (i.e. for 115 V 50/60 Hz). The demand will mainly come due to compliance with more strict energy regulations in the near future.

The controller can be modified to fit all other cabinet types as well where energy efficiency is a major buying criterion.