Challenges for ULT Freezers Technology

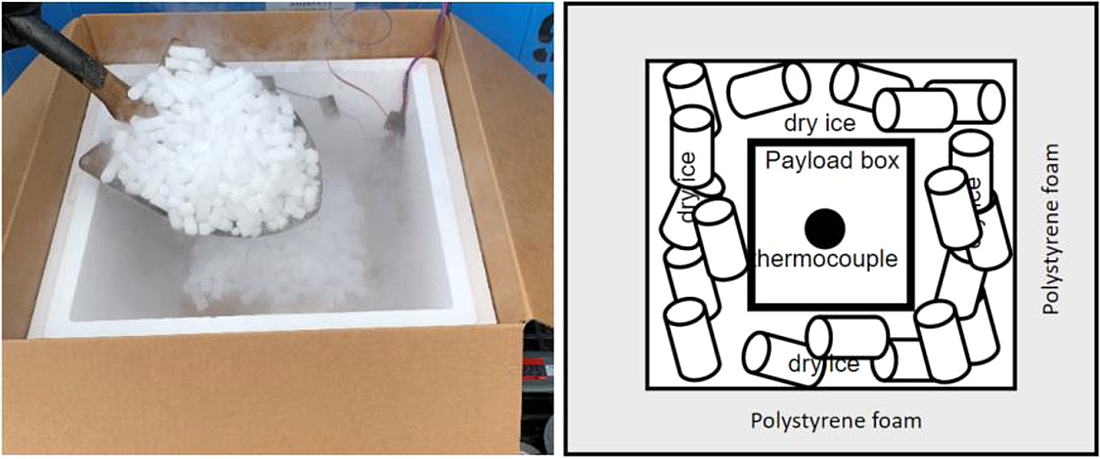

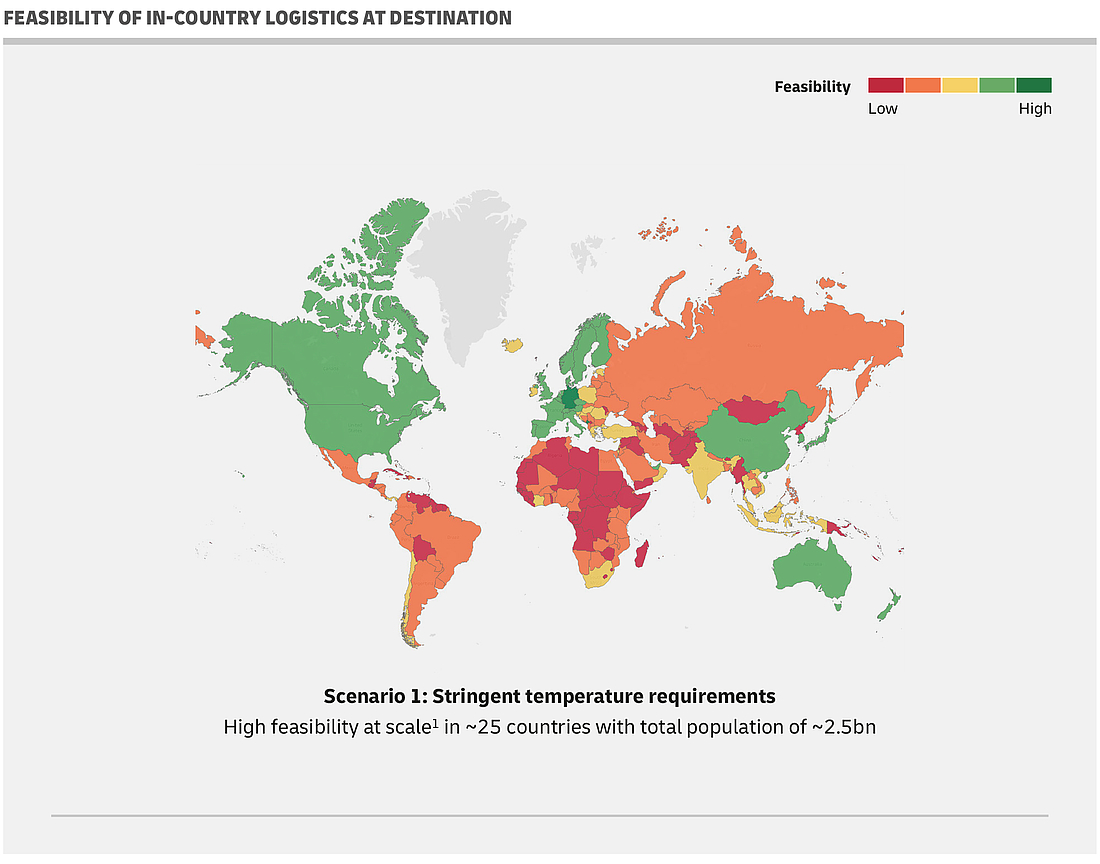

An ultra-cold freezer stores contents at temperatures down to -86 °C. ULT freezers are vital in the storage of critical material in medical research facilities, labs, hospitals, and anywhere valuable samples need to be stored safely. Also needed throughout the cold chain infrastructure is a temperature-controlled supply chain that uses equipment and logistics to store, transport, and distribute products to prevent the degradation of temperature-sensitive materials and samples. Recently, they’ve become associated with their extensive use during the global health crisis associated with the vaccinations campaign to fight the COVID-19 pandemic (figure 9).

A power outage can cause loss of entire batches of vaccines vials

While a power outage can be annoying when it happens at home, for medical research, it can be an absolute disaster. The reliability of these freezers is fundamental to guarantee safe storage of the precious contents. To close the gaps in medical cold chain storage and distribution for ultra-low temperature, a new generation of equipment is required to increase reliability, reduce energy consumption, introduce green refrigerants, and feature a smaller carbon footprint.

The importance of maintaining low power consumption across the ULT cold chain

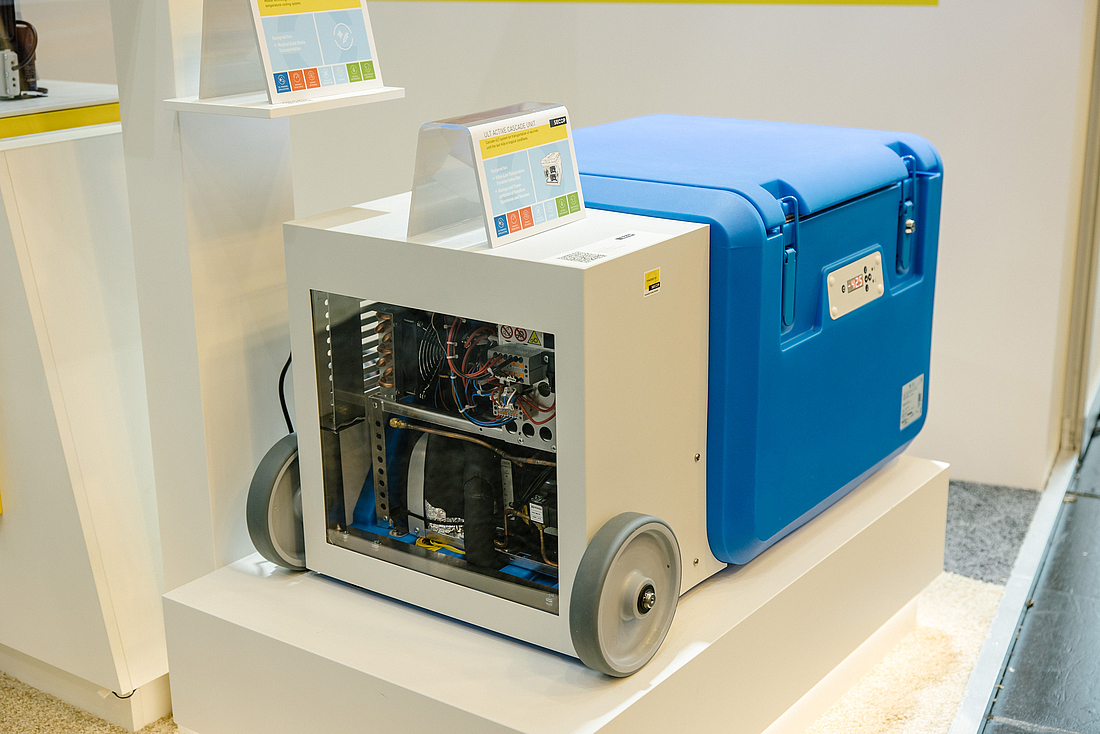

The focus on mRNA therapeutics requires ultra-low freezers for various steps in production, including decentralized into small clinics that requires ultra-low freezers that fit into smaller spaces.

The increased demand for cold chain development could drive up power consumption due to refrigeration’s intense energy use. ULT freezers consume an important amount of electrical energy since they must grant a low and stable temperature. In hospitals and labs, ultra-low freezers are identified as one of the larger sources of energy consumption. End-users thus need to carefully consider the energy consumption of ultra-low freezers. Ultra-low freezers aim at meeting the Energy Star and Energy Labelling requirements, and future products will have greater transparency in term sof energy consumption.

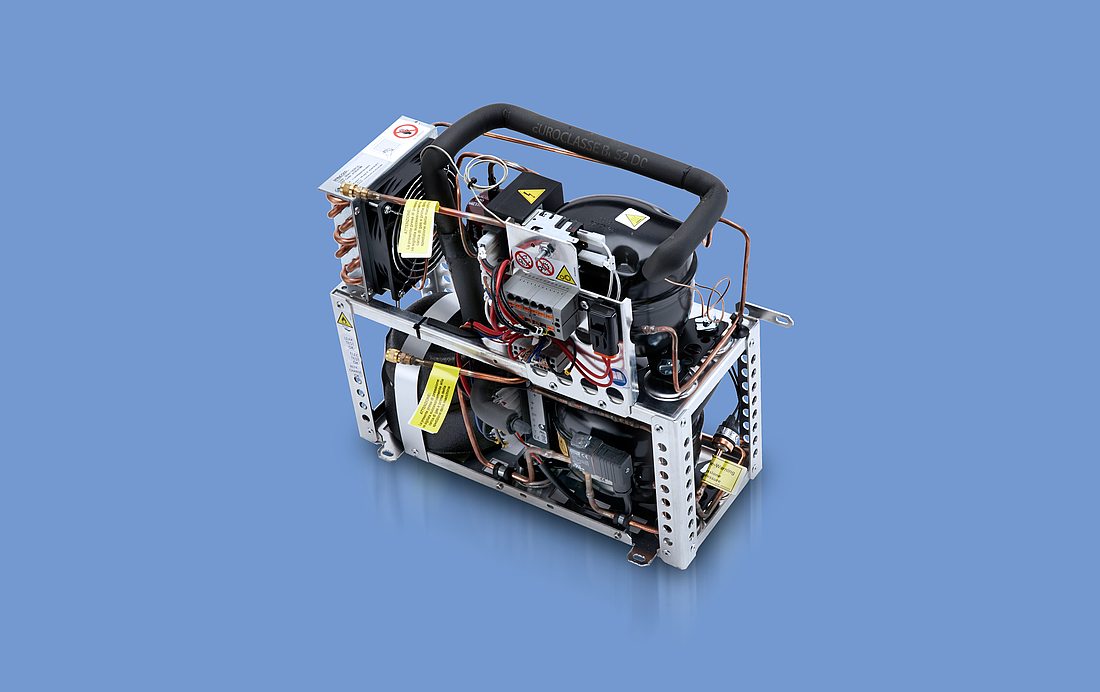

Variable speed technology and natural refrigerants can support the vaccines cold chain

To support the demand for lower energy consumption and higher efficiency for medical appliances, manufacturers are adopting new solutions such as variable-speed compressors. On top of reducing energy consumption this technology provides several additional benefits, from reducing noise to improving product longevity because it reduces stress on system components. By consuming less energy, these systems also emit less heat, thereby cutting air conditioning costs for installation areas.

At the same time, the regulatory landscape for cold storage is also evolving with the phasing out of hydrofluorocarbon (HFC) refrigerants linked to global warming. Natural refrigerant hydrocarbons such as ethane and propane have enabled the adoption of sustainable products that perform better.

Of course, sustainability needs to be balanced against product performance. The market must move towards more sustainable refrigerants and target as well improved efficiency to focus on further reducing energy consumption. However, these trends have to be carefully considered so that they do not reduce a product’s performances and ability to recover temperature quickly.

The ULT freezer: product reliability is fundamental

For ULT freezers in the medical cold chain, the key challenge is assessing reliability. When a ULT freezer goes down, the consequences are not limited to repair or replacement only. In many cases the freezer must be revalidated for biomedical use and the product moved to another location. The content inside these freezers is precious and any failure can cause serious setbacks in terms of time, money, and research. The reliability of the product is paramount.

The ULT freezers of today are equipped with monitoring systems that ensure the safety of their contents in the event of an unexpected incident.